Quality Assurance Activities

- QMS Documentation

- Monitoring Quality Trends

- Complaints Analysis

- Quality System Audit

- Customer Satisfaction Survey

Quality Control Activities

- Inward Material, inspection and testing.

- In process inspection and testing.

- Finished product inspection & testing.

- Preparation of relevant records and control.

Product Conformance

FCB Building product conform to SASO, ISO,ANSI, BS and EN norms

Quality Outcome

- Customer Satisfaction.

- Consistently developing product.

- On time Service.

- Value for Money.

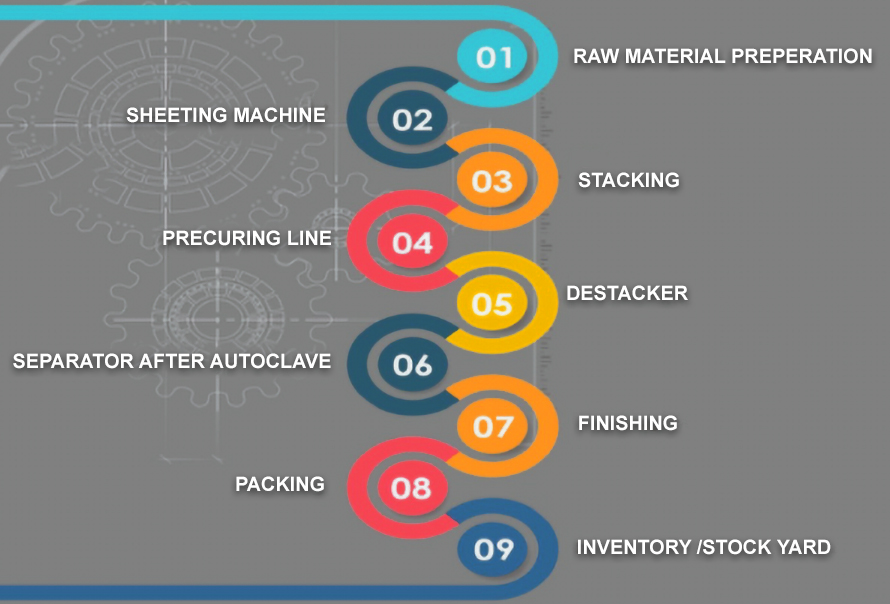

Operations

FCB is a modern choice light weight building & decoration board using cement as the binder and natural fiber as the reinforcement, manufactured by a process of pulping, emulsion, forming, pressing, autoclaving, drying and surface treatment. The color is gray. The factory surface treatment provides uniform thickness and a defined grain. The raw materials and the production process provide a better finish, a higher strength and superior mechanical characteristics when compared to competing products. FCB board is the finest product available in the Kingdom, the strength is higher, and waterproof performance is much better. So, fiber cement board is the highest quality product in the domestic and foreign building materials market.